Greaseblast™ - The Product

• Overview

• Installation explained

• Grease traps

Overview

Delivering the highest strength non-toxic vegetative bacteria on the market, GreaseBlast routinely dispenses multi-strained,

non-toxic bacteria directly into the drain line or grease trap to eliminate blockages, slow drainage, and bad odours, all of which

can have an untold effect on health and hygiene within the commercial kitchen.

The microorganisms are literally at work 24/7. They produce a biofilm in the drainage system so as waste is released it is

consumed on contact by the living bacterial colony.

GreaseBlast is designed to deliver the exact amount of highly concentrated vegetative bacteria into the drain line making

it simple to use. The bacteria within the system are replaced every 14 or 30 days depending on the amount of FOG being

disposed of, with the number of meals being prepared each day serving as a guide (please see installation instructions).

The GreaseBlast unit is an easy to use, cost effective solution to drainage issues and because it is an automatic system the

results are consistent every time whilst removing the need for costly service and maintenance requirements.

This effectively maintains free-flowing drains and eliminates all offensive odours as well as costly fines from water authorities.

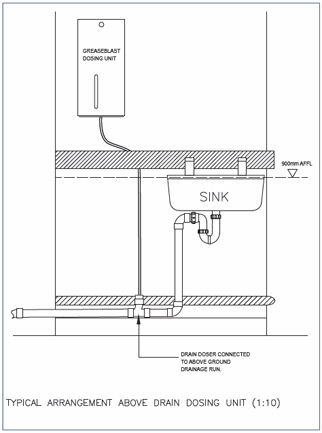

Installation Explained

Saving on valuable floor space, GreaseBlast is wall mounted and very simple to install and operate. With no water connection required, GreaseBlast can be fixed anywhere in a kitchen or facility and its stainless steel finish compliments existing fixtures and fittings. The GreaseBlast tube is simply inserted into a drain where the bacteria can be dispensed, with fixing kit, tubing and full instructions provided. The non-toxic, non-corrosive ready mixed containers of bacteria are incredibly easy to change over and install.

How frequently the container will need changing will depend on the number of meals being prepared each day.

More than 300 meals - dosing fluid is replaced every 14 days

Less than 300 meals - dosing fluid is replaced every 30 days

A simple fluid level display also shows the kitchen operator how much bacteria remains in the container and when it is close to requiring a replacement. The GreaseBlast unit is also key-lockable to ensure restricted access.

Grease Traps

The capacity of a grease trap will determine how effective it is at managing FOG. Cleaning out grease traps and accessing them

can be difficult and expensive. GreaseBlast offers a viable cost-effective solution. Installing a GreaseBlast system into the line

that feeds directly into the trap, the bacteria will keep grease trap FOG build-up permanently under control.